Non-Woven Fabric Printing Do’s and Don’ts: A Comprehensive Guide

Introduction In the promotional products industry, non-woven fabric has become increasingly…

Introduction

In the promotional products industry, non-woven fabric has become increasingly popular for its unique diversity in use combined with such low prices and being environmentally friendly, it tends to surpass traditional paper or other materials. Nevertheless, not all options give the same result and non-woven fabric needs special techniques to be printed on provided high-quality. This guide covers the do’s, and don’ts of non-woven fabric printing to help you create perfect promotional items every time.

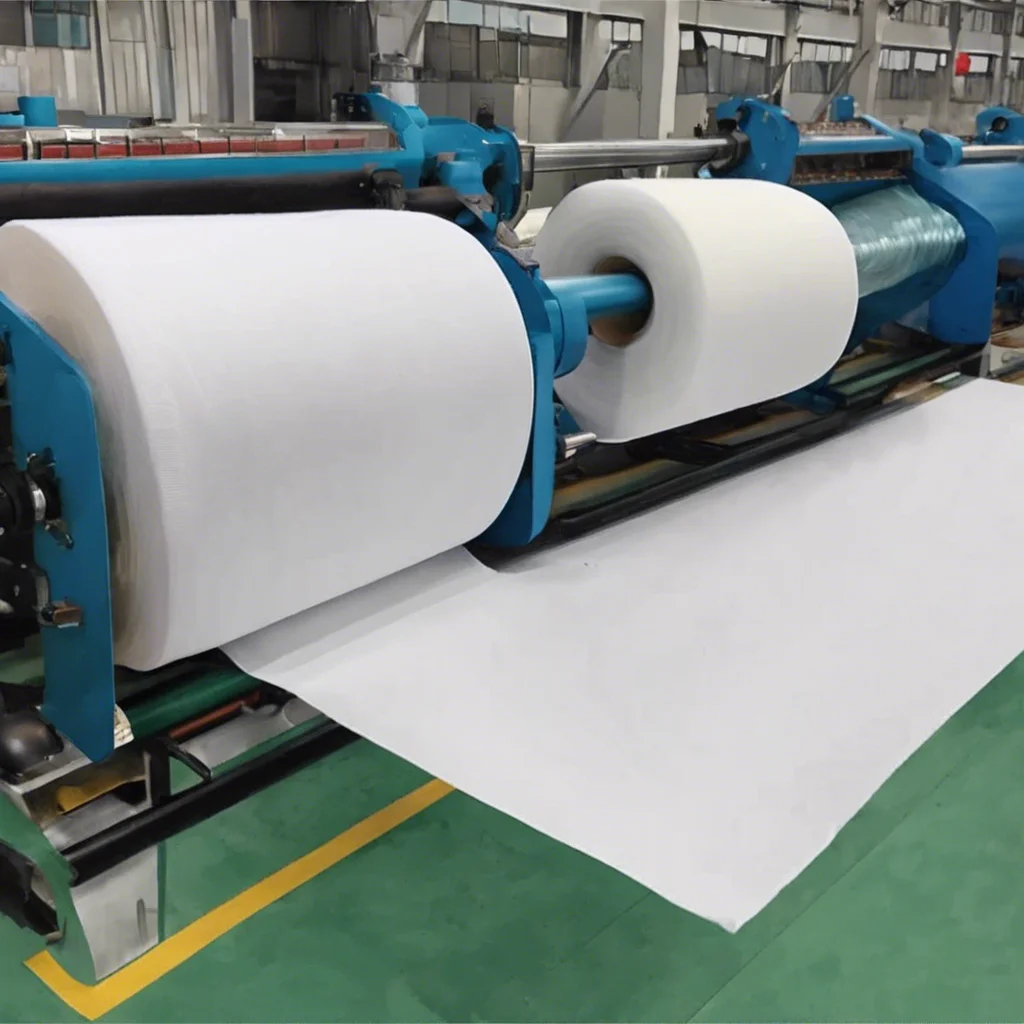

Understanding Non-Woven Fabric

We need to get a brief idea about what is Non-woven fabric before printing it. Non-woven fabric is a type of material where long fibers are held together through embryos worn, chemical and mechanical treatment. Non-wovens are different from traditional woven fabrics because they Do not need weaving or knitting, and the resultant fabric is a lot more versatile than its woolen counterpart making it perfect for promotional tote bags as well as aprons yet another branded thing.

Do’s of Non-Woven Fabric Printing

- Choose the Right Printing Method

- Test Print on a Sample

- Think About Fabric Color

- Use Proper Pre-Treatment

- Maintain Clean Equipment

Choose the Right Printing Method

Selecting the appropriate printing method is crucial for achieving successful prints on non-woven fabric. Some recommended methods include:

- Screen Printing: Ideal for large quantities and simple designs, providing vibrant and durable results.

- Heat Transfer Printing: Suitable for intricate and multicolored graphics using heat to transfer designs onto the fabric.

- Digital Printing: Offers excellent precision and flexibility for high-resolution images and smaller batches.

- Digital Printing: Offers excellent precision and flexibility for high-resolution images and smaller batches.

Test Print on a Sample

Always conduct a test print on a sample of the non-woven fabric before proceeding with a full production run. This allows you to evaluate ink adhesion, color accuracy, and overall print quality. Adjust settings and techniques based on test print results to ensure the best possible outcome.

Don’t: Use Water-Based Inks

Water-based inks are generally not recommended for non-woven fabric printing. These inks can bleed and fade quickly, leading to poor print quality and durability. Instead, opt for plastisol inks or other ink types specifically formulated for non-woven materials to ensure vibrant and long-lasting prints.

Do: Test Print on a Sample

Before proceeding with a full production run, always conduct a test print on a sample of the non-woven fabric. This step allows you to evaluate the ink adhesion, color accuracy, and overall print quality. Adjust your settings and techniques based on the results of the test print to achieve the best possible outcome.

Don’t: Overload with Complex Designs

While non-woven fabric can handle a variety of designs, overly complex and detailed graphics may not translate well. Simplify your designs to ensure clarity and visibility. Avoid intricate details that could become muddled or lost during the printing process.

Do: Consider Fabric Color

The color of the non-woven fabric can significantly impact the appearance of your print. Lighter-colored fabrics work well with most ink colors, while darker fabrics may require a white underbase to make the colors pop. Keep this in mind when designing your prints and choosing your fabric colors.

Don’t: Ignore Heat Settings

Heat plays a crucial role in non-woven fabric printing, especially for methods like heat transfer printing. Incorrect heat settings can result in poor adhesion, fading, or even damage to the fabric. Follow the manufacturer’s guidelines for heat settings and pressure to achieve optimal results.

Do: Use Proper Pre-Treatment

Pre-treatment can enhance ink adhesion and print quality on non-woven fabric. Depending on the printing method, this may involve applying a primer or pre-coating the fabric. Ensure that you follow the recommended pre-treatment process for your chosen printing technique.

Don’t: Rush the Drying Process

Allow sufficient time for the printed designs to dry and cure properly. Rushing this process can lead to smudging, fading, or poor durability. Follow the recommended drying times for your chosen ink and printing method to ensure the longevity of your prints.

Do: Maintain Clean Equipment

Clean and well-maintained equipment is essential for achieving high-quality prints on non-woven fabric. Regularly clean screens, squeegees, and other printing tools to prevent ink buildup and contamination. Proper maintenance ensures consistent and professional results.